-

OK NiFe-Cl-A

A nickel-iron cored electrode for joining normal grades of cast iron, such as grey-, ductile- and malleable irons. It is also suitable for rectification and repair of these grades and for joining them to steel. Deposition is done on cold or slightly preheated cast iron. The electrode produces a weld metal stronger and more resistant to solidification cracking than that of the pure nickel electrode type. It is specially suited for high duty welds in ductile irons and for welding grey irons with increased contents of sulphur and phosphorous. Typical applications include repair of pump bodies, heavy machine sections, gear teeth, flanges and pulleys.

-

OK Tigrod 12.62

A tripple desoxidized copper coated rod designed for GTAW of mild and fine grained structural- and pressure vessel steels as well as ship building steels. The rod is capable of producing high quality welds in semi-killed and rimmed steel as well as steel of various carbon levels. Because of added desoxidants, Al-Ti-Zr, the rod can also be used for welding steels with a rusty or dirty surface, without any sacrifice of weld quality.

-

OK Tigrod 12.64

OK Tigrod 12.64 is a copper-coated Mn-Si-alloyed W4Si1/ER70S-6 solid rod for the GTAW of non-alloyed steels, as used in general construction, pressure vessel fabrication and shipbuilding. It has a slightly higher manganese and silicon content than OK Tigrod 12.61 to increase the weld metal strength. This also promotes low sensitivity to surface impurities and contributes to smooth, sound welds.

-

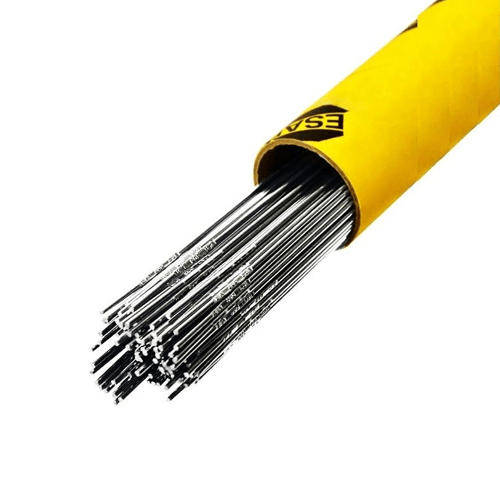

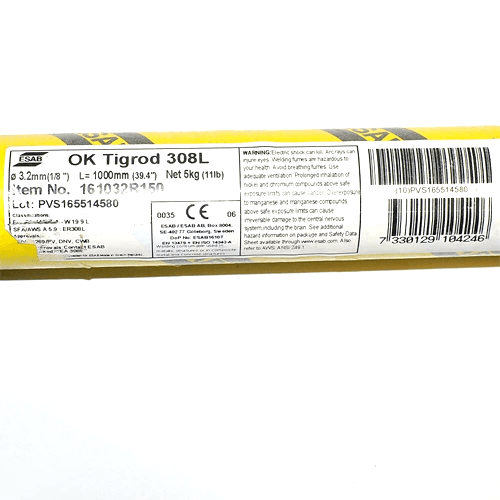

OK Tigrod 308L

OK Tigrod 308L has a good general corrosion resistance. The alloy has a low carbon content which makes this alloy particularly recommended were there is a risk of intergranular corrosion. The alloy is widely used in the chemical and food processing industries as well as for pipes, tubes and boilers. For joining of stainless steels of 18% Cr – 8% Ni-type with low carbon content and Nb-stabilized steels of the same type if the service temperature will not exceed 350°C. Can also be used for welding of Cr-steels except in sulphur rich environments.

-

OK Tigrod 309L

Bare corrosion resisting chromium-nickel welding rod for welding of similar steels of 24% Cr, 13% Ni types. The alloy is also used for welding of buffer layers on CMn steels and welding of dissimilar joints. When using the wire for buffer layers and dissimilar joints it is necessary to control the dilution of the weld. OK Tigrod 309L has a good general corrosion resistance. When used for joining dissimilar materials the corrosion resistance is of secondary importance.

-

OK Tigrod 316L

Bare corrosion resisting chromium-nickel-molybdenium welding rods for welding of austenitic stainless alloys of 18% Cr – 8% Ni and 18% Cr – 10% Ni – 3% Mo-types. OK Tigrod 316L has a good general corrosion resistance, particularly against corrosion in acid and chlorinated environments. The alloy has a low carbon content which makes it particularly recommended were there is a risk of intergranular corrosion. The alloy is widely used in the chemical and food processing industries as well as in ship building and various types of architectual structures.

-

OK Tigrod NiCr-3

Bare Ni-Cr rods for welding of high alloyed heat-resisting and corrosion resisting materials, 9%Ni-steels and similar steels with high notch toughness at low temperatures. Also for joining of dissimilar metals of the types mentioned. The weld metal has very good mechanical properties at high and low temperatures. Good resistance to stress corrosion.

-

OK Weartrode 55 HD

A general purpose hardfacing electrode depositing a semi corrosion resistant martensitic steel with a hardness of about 57 HRC. The electrode is specially suitable for hardfacing parts exposed to different forms of abrasive and impact wear, e.g. farming equipment, forestry tools, loading machines and mixers.