Browse 8000+ products

Welding Consumables

Welding Machines

Welding Accessories

Cutting Machines

Workshop Equipment

View all Categories

Featured products

-

OK Flux 10.71

OK Flux 10.71 is a neutral, bonded flux intended primarily for multipass butt and fillet welding of carbon and low alloy steels. It combines outstanding welding performance with excellent weld properties. OK Flux 10.71 is suitable for use with AC and DC, single and multiwire systems at currents up to 1000 amps. It should not be used in applications where there is heavy rust or mill scale on the base plate. Among the many areas where OK 10.71 is used are general structural welding, bridge fabrication, heavy equipment fabrication, and line pipe welding.

-

Renegade ET 300i

The Renegade TIG are inverter based High frequency TIG (HF) and MMA/Stick machines with extreme power to weight ratio. The compact format makes it easy to carry and bring to any jobsite. Combined with high duty cycle and the ability to run the machine on long mains and welding cable makes this a superior welding machine for both on-and off site applications.

The machine has an automatic input voltage sensor and can operate with any input voltage between 208V and 528V in 3-phase and 230V in single phase.

-

Cutmaster 40

ESAB Cutmaster 40 is one of the most affordable, highest quality 110V/230V 12mm(1/2”) plasma systems on the market. As part of the TRUE Series, you can rely on the Cutmaster 40 to cut all day at its recommended cutting capacity and to pack more punch when you need it. Comes complete with carry bag, power supply with work lead and ground clamp, 6.1m SL60 torch, operating manual and DVD.

-

OK Tigrod 309L

Bare corrosion resisting chromium-nickel welding rod for welding of similar steels of 24% Cr, 13% Ni types. The alloy is also used for welding of buffer layers on CMn steels and welding of dissimilar joints. When using the wire for buffer layers and dissimilar joints it is necessary to control the dilution of the weld. OK Tigrod 309L has a good general corrosion resistance. When used for joining dissimilar materials the corrosion resistance is of secondary importance.

-

25.22.2.LMn

25.22.2.LMn is a manganese alloyed chromium-nickel-molybdenum filler material used for welding UNS S31050, 1.4466 or UNS S31603, 1.4435. The weld deposit has excellent low temperature toughness that makes it suitable for joining stainless steels for cryogenic service. 25.22.2.LMn has extensively been used successfully in all critical high-pressure units of modern urea processes, such as: Stripper tubes – Stamicarbon, Montedison IDR Outerlayer of bimetallic ( stripper tubes) – Saipem Ferrules – All processes Carbamate condensers – All processes Decomposers – Montedison Reactor coils – UTI 25.22.2.LMn has also found extensive use in other corrosive environments in fertilizer plants, such as: – Nitric acid cooler/condensers cooled with polluted cooling water – Heating coils and pipe in NPK plants – Norsk Hydro process It is used for TIG-welding.

-

OK 76.18

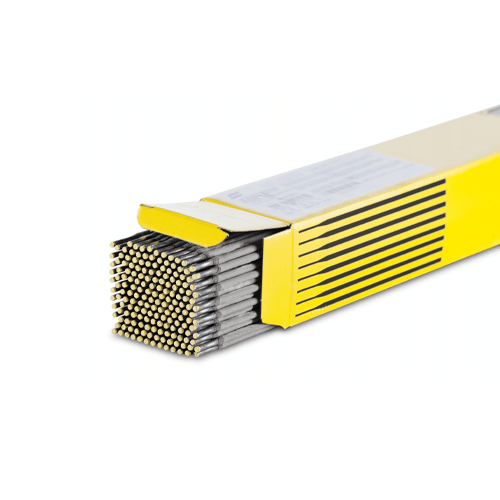

OK 76.18 is an LMA electrode for welding creep-resistant steels of the 1.Cr0.5Mo type. The electrode welds with a quiet, stable arc and produces a minimum of spatter loss. OK 76.18 deposits a weld metal which is resistant to cracking as well as porosity. The scaling temperature of the weld metal is about 575°C.

Build, Maintain, Repair or Operate a Facility