-

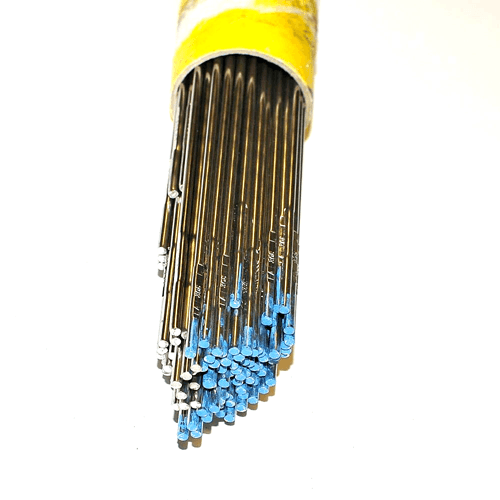

OK Tigrod 308L

OK Tigrod 308L has a good general corrosion resistance. The alloy has a low carbon content which makes this alloy particularly recommended were there is a risk of intergranular corrosion. The alloy is widely used in the chemical and food processing industries as well as for pipes, tubes and boilers. For joining of stainless steels of 18% Cr – 8% Ni-type with low carbon content and Nb-stabilized steels of the same type if the service temperature will not exceed 350°C. Can also be used for welding of Cr-steels except in sulphur rich environments.

-

OK Tigrod 309L

Bare corrosion resisting chromium-nickel welding rod for welding of similar steels of 24% Cr, 13% Ni types. The alloy is also used for welding of buffer layers on CMn steels and welding of dissimilar joints. When using the wire for buffer layers and dissimilar joints it is necessary to control the dilution of the weld. OK Tigrod 309L has a good general corrosion resistance. When used for joining dissimilar materials the corrosion resistance is of secondary importance.

-

OK Tigrod 316L

Bare corrosion resisting chromium-nickel-molybdenium welding rods for welding of austenitic stainless alloys of 18% Cr – 8% Ni and 18% Cr – 10% Ni – 3% Mo-types. OK Tigrod 316L has a good general corrosion resistance, particularly against corrosion in acid and chlorinated environments. The alloy has a low carbon content which makes it particularly recommended were there is a risk of intergranular corrosion. The alloy is widely used in the chemical and food processing industries as well as in ship building and various types of architectual structures.

-

OK Tigrod NiCr-3

Bare Ni-Cr rods for welding of high alloyed heat-resisting and corrosion resisting materials, 9%Ni-steels and similar steels with high notch toughness at low temperatures. Also for joining of dissimilar metals of the types mentioned. The weld metal has very good mechanical properties at high and low temperatures. Good resistance to stress corrosion.

-

OK Weartrode 55 HD

A general purpose hardfacing electrode depositing a semi corrosion resistant martensitic steel with a hardness of about 57 HRC. The electrode is specially suitable for hardfacing parts exposed to different forms of abrasive and impact wear, e.g. farming equipment, forestry tools, loading machines and mixers.

-

OK Weartrode 60 T

Electrode producing a weld metal with coarse chromium carbides in an austenitic matrix. Suitable for surfacing worn parts exposed to abrasion and wear by coal, ore or other minerals. Typical applications include earth-moving machines, mixers, feeder screws, dust exhausters and crushers. It can also be used on components operating in corrosive environments and/or at elevated temperatures.

-

Pipeweld 6010 Plus

Cellulosic-coated electrode designed for welding of pipes and pipelines in all positions using conventional and stovepipe techniques. Deep penetration in all positions especially vertical down. Suitable for welding pipe steels API 5L up to X56, root pass up to X80. Even though DC+ is advised and easier to control, DC- can be used for root run.

-

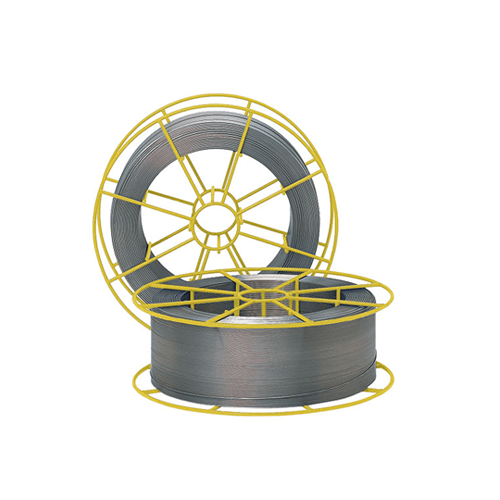

Shield-Bright 316L

FCAW wire for low carbon 18%Cr – 12%Ni – 2%Mo stainless steel for all-position welding. For welding type 316 stainless. Contains molybdenum which resists pitting corrosion induced by sulphuric and sulphurous acids, chlorides and cellulose solutions. Used widely in the rayon, dye and paper making industries. Carbon content 0.04% maximum.