-

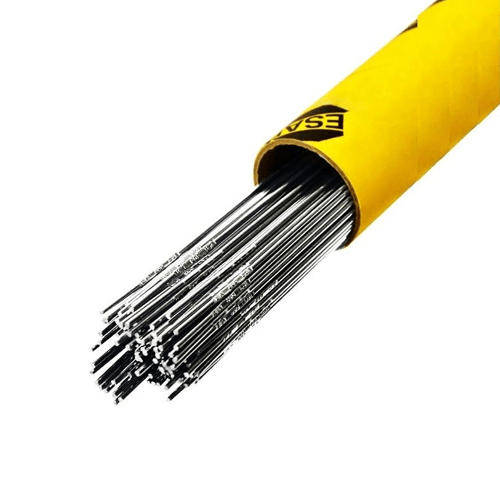

OK Autrod 5356

OK Autrod 5356 is the most widely used welding alloy and can be classified as a general purpose type filler alloy. OK Autrod 5356 is typically chosen because of its relatively high shear strength. The 5XXX alloy base material, welded with OK Autrod 5356, with a weld pool chemistry greater than 3 % Mg and service temperatures in excess of 65 °C are susceptible to stress corrosion cracking. The alloy is non-heat treatable.

-

OK Flux 10.62

ESAB OK Flux 10.62 is a high basicity, neutral, bonded flux intended primarily for multipass butt welding carbon and low alloy steel plate. OK Flux 10.62 produces weld metal that is very clean metallurgically and exhibits exceptional impact toughness at low temperatures. OK Flux 10.62 provides well-shaped beads and free peeling slag. Applications for OK Flux 10.62 include offshore oil rigs (meets CTOD requirements), fracture critical bridge members, ship construction, pressure vessels, and tank cars. It is suitable for use with AC and DC, single and multiwire systems at currents up to 1000 amps. OK Flux 10.62 should only be used in applications where the base plate is free of rust and mill scale.

-

OK Flux 10.71

OK Flux 10.71 is a neutral, bonded flux intended primarily for multipass butt and fillet welding of carbon and low alloy steels. It combines outstanding welding performance with excellent weld properties. OK Flux 10.71 is suitable for use with AC and DC, single and multiwire systems at currents up to 1000 amps. It should not be used in applications where there is heavy rust or mill scale on the base plate. Among the many areas where OK 10.71 is used are general structural welding, bridge fabrication, heavy equipment fabrication, and line pipe welding.

-

OK Ni-Cl

OK Ni-CI is a nickel cored electrode for joining normal grades of cast iron, such as grey-, ductile- and malleable irons. It is also suitable for rectification and repair of these grades and for joining them to steel. Deposition is done on cold or slightly preheated cast iron. Weld metal is well machinable. Typical applications are repair of cast iron parts such as cracks in engine blocks, pump housings, gear boxes, frames as well as foundry defects.

-

OK NiFe-Cl-A

A nickel-iron cored electrode for joining normal grades of cast iron, such as grey-, ductile- and malleable irons. It is also suitable for rectification and repair of these grades and for joining them to steel. Deposition is done on cold or slightly preheated cast iron. The electrode produces a weld metal stronger and more resistant to solidification cracking than that of the pure nickel electrode type. It is specially suited for high duty welds in ductile irons and for welding grey irons with increased contents of sulphur and phosphorous. Typical applications include repair of pump bodies, heavy machine sections, gear teeth, flanges and pulleys.

-

OK Tigrod 12.62

A tripple desoxidized copper coated rod designed for GTAW of mild and fine grained structural- and pressure vessel steels as well as ship building steels. The rod is capable of producing high quality welds in semi-killed and rimmed steel as well as steel of various carbon levels. Because of added desoxidants, Al-Ti-Zr, the rod can also be used for welding steels with a rusty or dirty surface, without any sacrifice of weld quality.

-

OK Tigrod 12.64

OK Tigrod 12.64 is a copper-coated Mn-Si-alloyed W4Si1/ER70S-6 solid rod for the GTAW of non-alloyed steels, as used in general construction, pressure vessel fabrication and shipbuilding. It has a slightly higher manganese and silicon content than OK Tigrod 12.61 to increase the weld metal strength. This also promotes low sensitivity to surface impurities and contributes to smooth, sound welds.